Scope of services

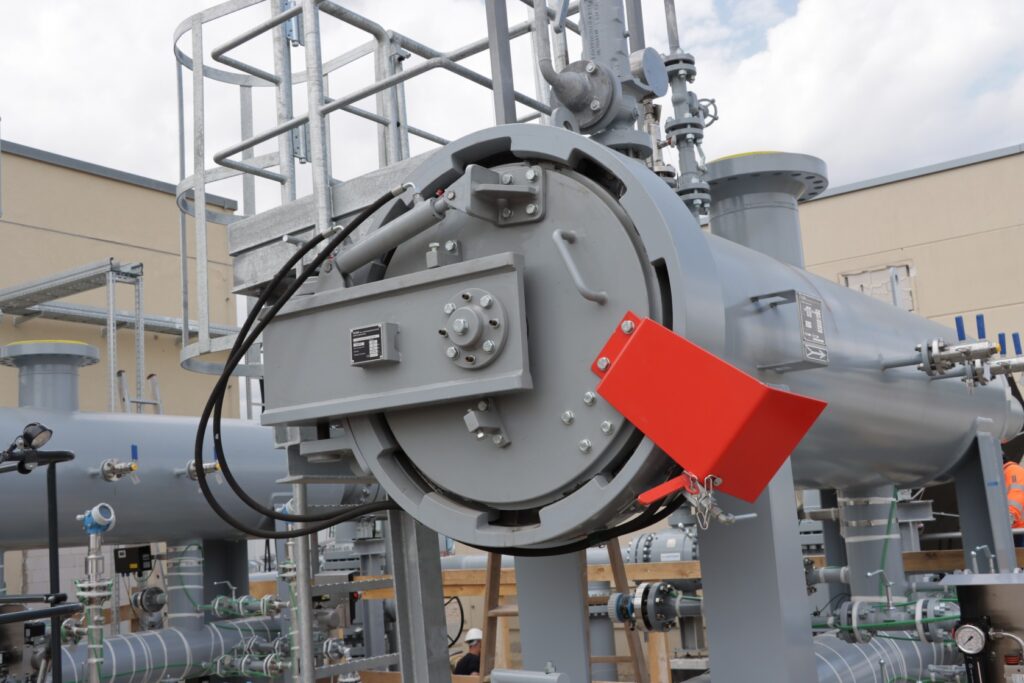

Conversion of the plant from L-gas to H-gas, including the installation of piping for two feed-in filters, the installation of a new sales meter for injection and withdrawal and a volume control system for withdrawal as well as the integration of compressors V4 and V5 and the drying plant. The new gas and water cooler of the V4 compressor unit and the two new hot water boilers of the preheating system were re-piped. In addition, the existing instrument air supply was extended and adapted and the LP blower was reconnected.

Work carried out:

Pipeline construction:

Structural/civil engineering: